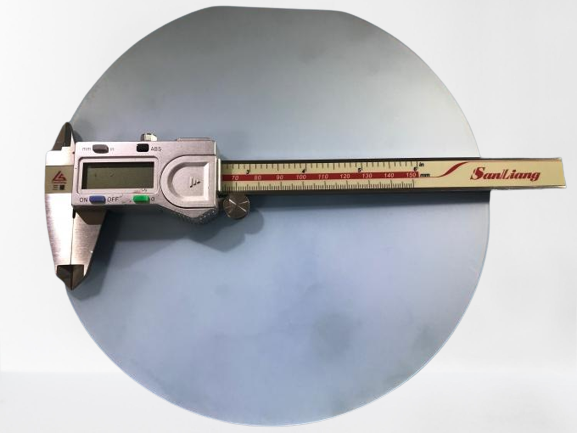

4 wafer

4 wafer : At present, although the market has a large demand for silicon wafers of various sizes, such as those larger than 12 inches, it is because the demand for partial electronic equipment and semiconductors is the largest and the most popular. As one of the silicon wafers, the tools needed to manufacture semiconductors are very expensive, and traditional systems still operate well, customers choose those that are easier to use and store. 4 wafer is a good choice for their small batch production.

4 wafer

Free Standing gan Wafer | Single Crystal Substrates

Si Doped Undoped Laser Device Gallium Nitride Wafer

300mm Gan Wafer | Gallium Nitride Wafer For Power Micro LED

8 Inch 12 Inch 6Inch gan Wafer

2 Inch 4 Inch GaN Wafer | Gallium Nitride Wafer

4inch 6inch GaN-ON-SiC EPI layer

4 wafer

What is a 4 wafer ?

The 4 wafer is a circular disk made of pure silicon, which is widely used in diodes and integrated circuits. Of course, transistors are produced.

MCC has widely used the four inch silicon wafer. The diameter of the lens is usually four inches, that is, about 100 mm, and the thickness is several hundred microns. It is usually made of single crystals, which is a high–urity raw material with a specific crystal structure.

The production steps of silicon chip are actually relatively simple. A large silicon crystal is grown from it, the crystal is cut into thin silicon chips, and then the silicon chip is polished to a high degree of flatness and smoothness. The silicon chip is used as the base for the production of microelectronic devices, which involves various processes such as photolithography.

In computer smartphones and other consumer electronics, silicon wafers are widely used. They are also used to produce solar cells, convert solar energy into electricity, and be used in various other industrial and scientific fields.

How much does a 4 wafer silicon chip cost?

Several different grades of silicon chips are available for you to choose, each of which has its own characteristics and corresponding price range. For example, high–qurity monocrystalline silicon chips may be more expensive than low–quality polycrystalline silicon chips. In terms of cost, the price of 4–nch silicon chips may vary depending on the quantity of silicon chips purchased. It is the cost of inch silicon chips. Generally speaking, the difference is large, Its determinants are also diversified. The price basically ranges from a few dollars to several hundred dollars. The price of high–uality silicon chips is generally high. However, you must note that the cost of 1.4 inch silicon chips is only lettuce. The total cost of microelectronic devices is very small, and its proportion is very small. There are many other steps involved in the production process. These steps will greatly increase. The cost of the 4–nch silicon chips we provide, including photolithography, etching, and deposition,