Indium Phosphide Wafer (InP wafer) Substrates

Indium Phosphide Wafer is a raw material of semiconductor structure, which is a face centered cubic crystal with band gaps.It can be used in some high-frequency electronic products, and its electron speed should be much higher than that of ordinary semiconductors products, so a crystalline indium phosphide wafer has a low-energy quantum of indium.

As a compound, it is also known as the indium gallium arsenide, and it has very similar characteristics to GaAs, that is to say, the biggest difference is that it carries a high-frequency alloy of gallium and indium.

Si Doped Undoped Laser Device Gallium Nitride Wafer

300mm Gan Wafer | Gallium Nitride Wafer For Power Micro LED

Indium Phosphide Wafer - inp wafer

Indium phosphide (InP wafer), used to make microelectronics and optoelectronic chips, is a relatively excellent semiconductor material, and its role is determined by some key factors.

Indium phosphides are manufactured with complex epitaxial growth processes, which is the biggest difference between them and turtles. The most common method we use is organometallic chemistry, vapor deposition and molecular beam epitaxy. Of course, from a value perspective, the value will be higher.

Although Indium phosphide (InP) has significant challenges in manufacturing, it can achieve some performances that silicon cannot be covered by its original design. It is used in some electronic and optoelectronic devices.

They are the basic materials for high-frequency communication electronics and fiber optic applications. The technology for manufacturing at the cost of Indium phosphide (InP) wafers continues to improve, and we are actively investing in research and development in this area.

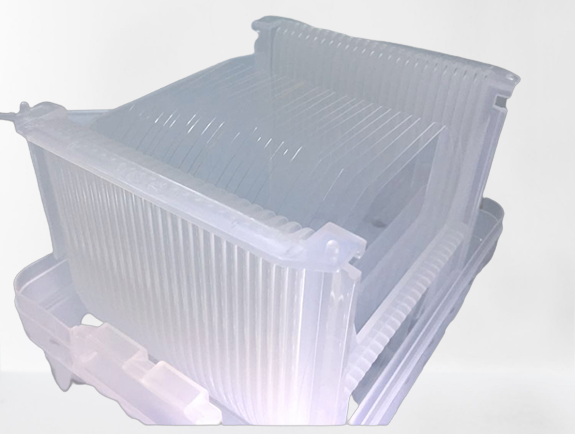

The size range of Indium Phosphide Wafers is also quite broad, usually two inches and 4 inches are common sizes. During this period, we can customize the range and produce larger-sized wafers, which makes production more difficult for us.

At the same time, indium phosphide can also be used to manufacture light-emitting diodes and lasers, as its characteristic of having gaps is very suitable for fiber optic communication.

The high performance equipment required for research in telecommunications, medical technology, military systems, and other fields, Indium Phosphide Wafer can help you achieve some of its performance , as it can go beyond some of the technological ranges that sic cannot enjoy.

The Indium Phosphide Wafer is still an important raw material for optoelectronics and high-frequency electronics, although it has certain difficulties in production.

Indium phosphide (InP) wafer have higher electron saturation velocity and thermal conductivity.It has higher resistance to breakdown of ionization coefficients of the highest threshold voltage,

The Indium Phosphide (InP) wafer produced by reaction at a temperature of 400 ℃ is manufactured through silver iodide and white phosphorus. It can also be manufactured through high-pressure and high-temperature integrated cleaning components.

This type of wafer is an interesting method that involves thermal decomposition of phosphorus compounds. A multi-stage process is employed in the manufacturing to ensure the highest quality product.

As a widely used raw material, it has become the starting point of hierarchy throughout the entire chip system, including in the fields of optical detection, growth, amplification, routing and combination, as well as high-speed switching and modulation. It can be used to generate high-speed on/off modulators, amplifiers, and passive waveguides that connect these electronic devices.

Indium phosphide InP single crystal wafers are used in telecommunications and microwave technology for components of fiber-optic communication systems

We sincerely welcome you to inquire and purchase our inp wafer, which will help you achieve your pursuit of high performance in your production. Please contact us now.

Indium Phosphide (InP) Wafers

Meanwhile, the Indium phosphide used for semiconductor is usually divided into P type and N type on the surface. Of course, when producing N type, we need to provide some additional steps to complete this production.