al2o3 substrate Supplier & Manufacturer in China

al2o3 substrate : This product has good heat resistance and wear resistance, while its high-strength mechanical properties are also very significant, and the dielectric loss is very small. These advantages make it one of the very popular ceramic substrates. The surface of the alumina substrate is quite smooth, and it is equipped with good low porosity.

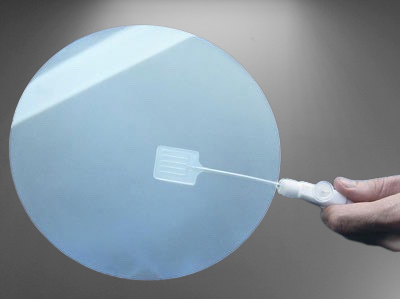

2 Inch A - Axis Sapphire Wafer For EPI

5 Inch Sapphire Wafer R Plane Dia 125mm

8 Inch Sapphire Wafer Dia 200 mm

Al2O3 single crystal substrate, <0001> 100mm Dia. x 0.9mm

12 Inch Sapphire Wafers Dia 300mm

4 inch Sapphire Wafer C-Plane Single or Double Side Polish Al2O3 Single Crystal

6 inch Sapphire Wafer C-Plane Single or Double Side Polish Al2O3 Single Crystal

Polished Alumina Substrate, Al2O3 | single crystal substrates

At present, it has become a high-quality raw material for microelectronics and optoelectronic substrates. The key advantage of aluminum oxide substrate is its high melting point, good thermal conductivity, and low conductivity, which are all its advantages. These advantages make it the foundation of many high-power and high-frequency heating devices.

The diameter range of aluminum oxide substrate is also very wide. We usually sell aluminum oxide, and its diameter is basically between 1 to 6 inches. Larger diameter alumina substrates ( Al2O3 Substrate ) have certain difficulties in the production process, and the polishing process is relatively difficult, and their value will be more expensive.

Aluminum oxide substrate has become an alternative product for semiconductors.Its chemical stability, mechanical stability and thermal stability make it a high-performance semiconductor material. Its unique performance is irreplaceable for many raw materials in the current market.

At present, aluminum oxide substrate is very suitable for use with high coefficient of thermal expansion and can be matched with various semiconductor materials such as potassium nitride and silicon carbide, which reduces defects caused by lattice mismatch when used for heteroepitaxy.

Main characteristics:

high wear & chemical resistance

heat resistant

high mechanical strength

Small dielectric loss

good thermal conductivity

high light reflection

0% water absorption

The application of alumina substrate is extremely extensive, as is well known, it can be used in LED lamps, photovoltaic equipment, or some high-frequency circuits and electronic products. It has good reliability and application ability, and is also widely used in some dangerous environments.

Our al2o3 substrate can be customized according to different thicknesses, and can be polished on one or both sides. We also provide unpolished aluminum oxide substrates, and our prices may vary slightly depending on the quantity. In terms of packaging, we provide safe and reliable export standard packaging forms to meet your requirements for obtaining high-quality al2o3 substrate.

Due to the high cost of alumina wafers and their strict requirements for surface finish, we need a good way to transport and store alumina substrates to avoid some damage. How can we achieve these standardized storage and transportation?

It needs you to first have good packaging materials to protect the alumina substrate itself, and then try to be careful and avoid collision and other factors during transportation. It is best to place the alumina substrate in a cool and dry place to avoid moisture, etc.

Welcome to inquire about our al2o3 substrate, and we will promptly provide you with pricing and product information.