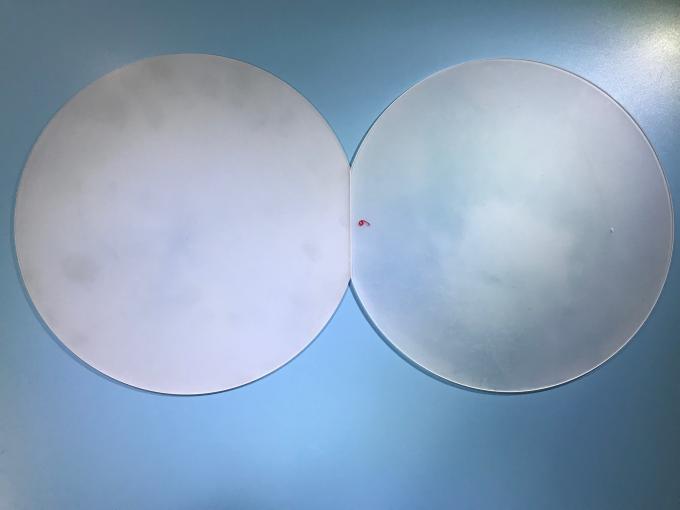

silicon carbide wafer

Silicon carbide wafer is a new type of semiconductor material, silicon carbide wafers has unique electrical properties and excellent thermal conductivity. In short wavelength photoelectric high temperature and radiation resistant applications, silicon carbide devices have been widely used in a large number of applications, and also widely used in high power and high temperature applications, such as silicon wafers and Shenhua Jiajinyuan. First, SiC wafer has a comprehensive performance.The material is SIC, N – type / Semi-insulating.

The silicon substrate is made by some special processes, which can be processed to ensure its degree, and then it is cut into independent chips to form semiconductors.

silicon carbide wafer | Your leading supplier & Manufacturer In China

Applications of silicon carbide wafers:

- LED.

- Optoelectronic devices.

- High temperature equipment.

- High power devices.

- High frequency devices.

- GaN epitaxial device.

XKH is a professional and well known silicon carbide wafer manufacturer. In this industry, we have rich industry experience and knowledge. You can be assured to tell us your demand for silicon carbide wafers. At the same time, we also provide some professional customized products, including Gallium Arsenide Wafer, Gallium Nitride Wafer, Sapphire Wafer, Silicon Wafer, Germanium Wafer (Ge wafer).

This is a compound containing carbon atoms and silicon atoms. Through chemical reaction and combination of carbon atoms, the result is a hard and very compact material, which makes silicon carbide the best choice in applications requiring high efficiency and low energy consumption.

silicon carbide wafer

At present, there are many types of Silicon Carbide Wafer, including 4H / 6H,the diameter has Ø 2″ / Ø 3″ / Ø 4″/ Ø 6″ , thickness range include 330 um ~ 500 um.N – type / Semi-insulating.There are production grade and research grade.We also provide you with customized products. If you just need this product, please contact us now.

Silicon carbide wafer has good thermo chemical and mechanical stability. It is a composite semiconductor material composed of tortoise and carbon. We provide a wide range of silicon carbide, wafers and wafers, including cutting wafers, semi insulating wafers, and grinding wafers.Polished wafers N Type. Xinkehui has developed advanced crystal growth and epitaxy technologies, manufacturing processes, engineering substrates and semiconductor devices, which make gold sources more stable in performance and lower in cost.At present, the different combination and arrangement of carbon atoms and silicon atoms make silicon carbide have a variety of lattice structures, such as 4h,6h,3c and so on.

In order to provide 4h and 6h silicon carbide substrates with high performance and apply them to dry epitaxial devices, power devices, high–emperature devices and optoelectronic devices, we have made a lot of work and efforts.Our family will makes every effort to develop large sized substrates and epitaxial technology.

Sic wafer is also used in cutting tools, sand wheels and wear esistant parts of pumps.

The resistance and thermal conductivity of silicon carbide to some high voltages make it the better material for various power electronic applications.