silcon wafer

silcon wafer is a kind of material needed for semiconductor manufacturing. It enriches all kinds of electronic equipment in our life. In our daily life, we rarely have the opportunity to introduce the real ghost chip. This super frequency disk is polished into a mirror, which can eliminate the tiny and irregular surface, making it one of the flattest objects in the world. It is super clean, almost free of particles and other impurities, with very high purity. This quality is necessary, When it is used as the substrate material of semiconductor.

silcon wafer

Free Standing gan Wafer | Single Crystal Substrates

Si Doped Undoped Laser Device Gallium Nitride Wafer

300mm Gan Wafer | Gallium Nitride Wafer For Power Micro LED

8 Inch 12 Inch 6Inch gan Wafer

2 Inch 4 Inch GaN Wafer | Gallium Nitride Wafer

4inch 6inch GaN-ON-SiC EPI layer

silcon wafer

silcon wafer

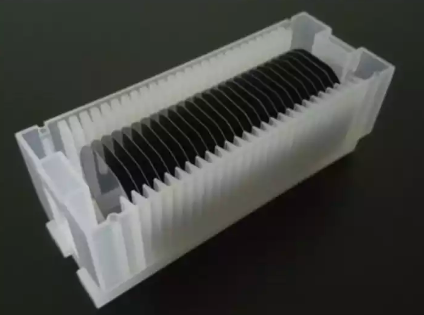

The silicon wafers produced by our company are single crystal silicon wafers with diameters ranging from 75mm to 300mm. These silicon wafers serve as the base of microelectronic devices, such as transistors, solar cells and integrated circuits. In other words, they constitute an important part of various electronic components and one of the best raw materials.

silcon wafer is the main material used to manufacture electronic devices, and also one of the important materials. Because it is an excellent electrical conductor and has many other characteristics, silicon is rich in resources and cheap, making it an essential raw material for large-scale production of electronic components. It is also relatively easy to process, and can be operated using various processes to create the required microelectronic devices.

Integrated circuits are probably the most famous electronic components made of silicon chips. These devices are composed of a series of interconnected transistors and other components. Because of the need to perform various functions, integrated circuits are widely used in various electronic devices, including computers, smartphones and other electronic products.

Silicon wafers are usually made by cutting a single crystal from a living boudoir into thin slices. The silicon chip produced by this is very pure, and it is also necessary to ensure that the body microelectronic components can work normally to such a high level.

After silcon wafer are sliced, they need to go through some processing steps, which can also be used in microelectronic components, including cleaning, polishing and application of various coatings. The wafer can also use photolithography to achieve its pursuit of performance.

This involves the use of light to transfer patterns to the surface of the chip, a process used to create tiny electronic components that process as electronic devices.

Once the silicon wafer is processed, it can be used to manufacture microelectronic components. The specific process used to manufacture specific equipment will depend on the required application and the type of equipment being manufactured. For example, the process of manufacturing solar cells will be different from that of manufacturing integrated circuits.

When we use silicon chips to make solar cells and convert sunlight into electric energy, the solar cells are composed of a series of processes, including the launch of Dichenghe Electromechanical City. The successful launch is often made of materials such as Shenlinggui, while the base layer is only made of meal powder silicon, and the cushion is usually made of aluminum. In addition to integrated circuits and solar cells, silicon chips are used to make other microelectronic devices, including sensors, LED lights and other electronic components. With the continuous growth of the demand for electronic equipment, the demand for silicon wafers is also growing. These silicon chips are an important part of the production of microelectronic equipment, and their importance will continue in the foreseeable future.