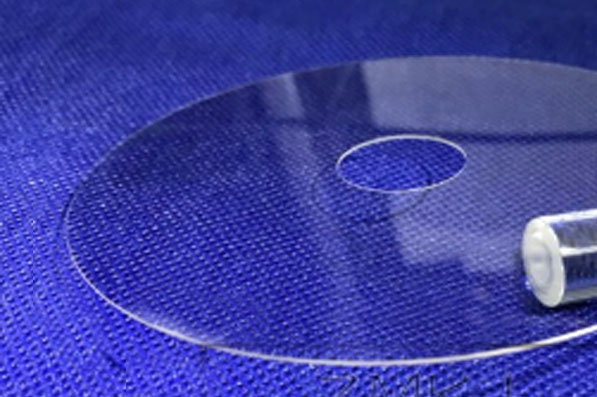

Lithium Tantalate Wafers Supplier Manufacturer in China

Lithium Tantalate Wafers : Characteristics are very obvious. It is a surface acoustic wave device, which can be provided by us according to different application scenarios and customers’ different specifications. the purity of this kind of raw material with a good degree that you use in your optical field reaches 99.99%. If you just need wafers and substrates or Lithium Tantalate Wafers, please contact us. Lithium Tantalate Wafers are widely used and simplest pyroelectric detectors.

2 Inch A - Axis Sapphire Wafer For EPI

5 Inch Sapphire Wafer R Plane Dia 125mm

8 Inch Sapphire Wafer Dia 200 mm

Lithium Tantalate Wafers | LITAO3

12 Inch Sapphire Wafers Dia 300mm

4 inch Sapphire Wafer C-Plane Single or Double Side Polish Al2O3 Single Crystal

6 inch Sapphire Wafer C-Plane Single or Double Side Polish Al2O3 Single Crystal

LiTaO3 lithium tantalate | LiTaO3 Wafers

Sapphire cannot display red because red is called red sapphire . It is a relatively rare type of alumina.From Sapphire wafer , its hardness reaches a Mohs hardness of 9, second only to diamonds, because diamonds have a hardness of only 10.

Sapphire is also widely used in decorative applications, such as durable windows, watch crystals, and some very thin electronic wafers. These are all considered very special talents to use, and it is also used as an insulator in some basic circuits and LEDs.His excellent transmittance is recommended for some special applications to use his chemical test single crystal alumina.

Main advantages and characteristics.

- The density is indeed depressed.

- High quality crystal.

- It can be used to improve the scale of semiconductor manufacturing.

- The tolerance range applicable to some specific equipment manufacturing requirements.

- It can optimize the performance and cost control of power electronic equipment.

Synthetic sapphire crystals have much better saturation and color than natural sapphires, as they are the total synthetic sapphire crystals that have been artificially processed. Of course, they are more susceptible to heat and scratches than natural sapphires. We need to properly keep our sapphire wafers to ensure their good performance.

The synthesized sapphire crystal is what we commonly refer to as an artificial gem, and it works in the laboratory. It can have the same performance as natural gemstones, and can be processed according to human needs to become the final sapphire wafer that people need.

Material: | Lithium Tantalate Wafers |

Diameter: | 1-100mm |

Thickness | 1-30mm |

Coating: | AR coating or uncoated |

Diameter Tolerance: | +/-0.1, +/-0.01mm |

Surface Flatness: | <L/4 at 632.8nm |

Surface quality | 60-40,40-20 |

Custom: | yes |

MOQ: | 1 pc |

We welcome you to discuss some deeper aspects of the performance and applications of synthetic sapphire, as well as some areas that need attention in market sales. We welcome you to inquire with us, and we are willing to share our experience, price, and control of raw materials with you one by one. Please contact us now, and we will become your best supplier and manufacturer of synthetic sapphire wafers.

We also produce Ge Substrate Germanium Wafers, and its dimensions include 2inch 3inch 4inch. There are also many types, divided into P Type / N Type.

Looking forward to your further communication on synthetic sapphire, and looking forward to your inquiry. Please contact us today.

Whatsapp: 0086-131 85 071071