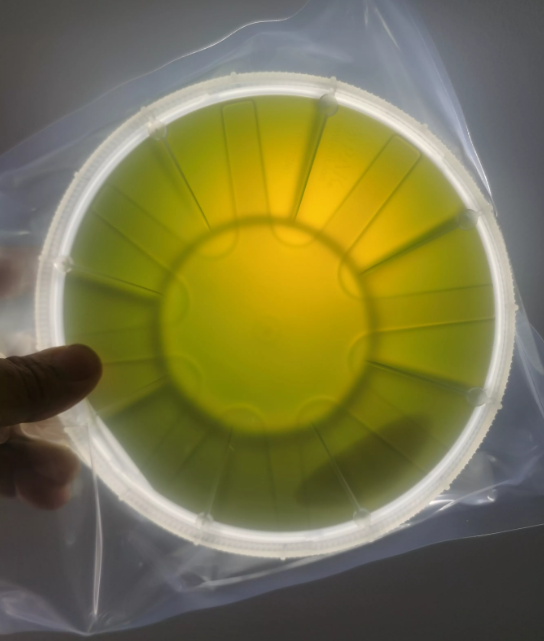

Silicone wafers

Silicone wafers :Wafer silicon is used to make microchips in electronic devices and semiconductors in chips. Due to the characteristics of current passing through silicon chips, integrated circuits are constructed from these semiconductors. When you choose Silicon waffer as the raw materials of your semiconductors, you will obtain a high performance that you expect, especially its purity.

Silicone wafers

Free Standing gan Wafer | Single Crystal Substrates

Si Doped Undoped Laser Device Gallium Nitride Wafer

300mm Gan Wafer | Gallium Nitride Wafer For Power Micro LED

8 Inch 12 Inch 6Inch gan Wafer

2 Inch 4 Inch GaN Wafer | Gallium Nitride Wafer

4inch 6inch GaN-ON-SiC EPI layer

Silicone wafers

Silicone wafers:

Purifying Silicon nitride

Silicon wafer is one of the most common and widely used raw materials in electronic products.

Silicon Glass has a very large surface area and is very light. It can be used in computers and semiconductor devices.

It is usually formed by silica sand, which is specially exploited for the electronic industry.

When Silicon use for semiconductor manufacturing, its advantages were very obvious. First of all, it had a relatively high purity.

The semiconductor manufacturing industry uses technologies ranging from handheld computers to unmanned aerial vehicles in a variety of applications. Almost every electronic device has a gray city. Some devices, including sensors, accelerators and optical sensors, use silicon wafers.

Silicon wafer | Silicon doping is a key component of integrated circuit, They are crystalline silicon wafers, which are used as the base of microelectronic devices.

When producing silicon wafers silicon carbide wafer, their surfaces must be free of defects. Keeping the surfaces clean can make the printing of circuit layout go smoothly.