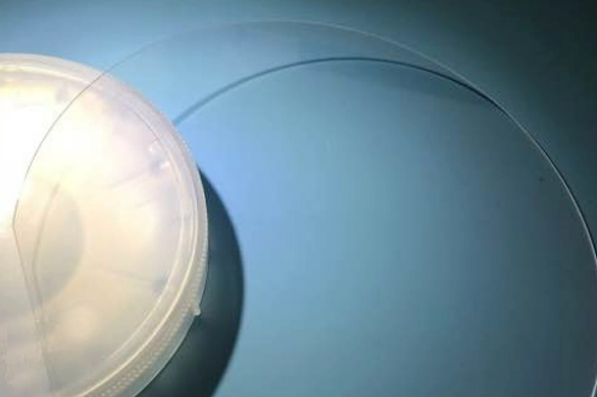

sapphire optical lens

As an innovative replacement for conventional glass lenses in the field of optics, sapphire has recently come to light. The answer is emphatically yes—sapphire lenses can indeed replace glass lenses, despite the fact that glass lenses have long dominated the market. Sapphire is a valuable stone prized for its tenacity and purity, and because of its special optical characteristics, it is the perfect material for lenses.

When compared to glass, sapphire lenses are exceptionally scratch-resistant, ensuring sharp vision even after extensive wear. Because of sapphire’s extraordinary hardness and unmatched endurance, it is a desirable material for a variety of uses, including high-end cameras and scientific instruments.

The exceptional thermal conductivity of sapphire lenses further ensures their stability even in extremely hot or cold environments. This characteristic makes them invaluable in industries where precision and reliability are paramount. The ability to manufacture sapphire lenses in intricate shapes further enhances their versatility, allowing for customized solutions tailored to specific optical needs.

What is a Sapphire Lens? | sapphire optical lens

A sapphire lens isn’t just any lens – it’s a marvel crafted from synthetic sapphire, a crystal form of aluminum oxide. This man-made sapphire inherits the extraordinary qualities of natural sapphire, making it a gem in optical technology. Meticulously crafted using advanced methods, these lenses guarantee precision and crystal-clear clarity. They’re not your everyday lenses; they’re a vital component in industries spanning aerospace, defense, medicine, and scientific research.

What makes sapphire lenses stand out? Their unmatched transparency across the electromagnetic spectrum. Picture this: from ultraviolet to near-infrared wavelengths, sapphire lenses offer unparalleled clarity. In fields where optical precision is non-negotiable, these lenses shine. Whether they’re capturing moments in high-end cameras, powering lasers, or enhancing medical devices, sapphire lenses deliver top-notch imaging quality. It’s no wonder they’re the go-to choice for both professionals and enthusiasts alike.

What is Optical Sapphire?

Aluminum oxide crystals that have been created in a lab are known as optical sapphire, also referred to as synthetic sapphire. Aluminum oxide powder is burned to high temperatures and gently cooled to form a single crystal using a procedure known as the Verneuil method to produce this special material. The resulting sapphire boasts exceptional purity and clarity, rivaling that of natural sapphire gemstones. As the second-hardest material after diamond on the Mohs scale, optical sapphire is recognized for being extremely resistant to scratches and abrasions.

Synthetic sapphire has very outstanding optical characteristics. Its high refractive index and low dispersion ensure minimal color distortion, providing true-to-life color representation. These properties, coupled with its exceptional hardness, make optical sapphire an ideal choice for precision optics, lenses, and windows used in diverse industries.

What is a Sapphire Crystal Lens Cover?

Various optical instruments employ sapphire crystal lens covers as a protective feature to cover their lenses. Since sapphire crystal lens covers are more durable and scratch-resistant than ordinary glass covers, they guarantee that the lens will not be harmed even in challenging conditions. Sapphire crystal lens covers offer outstanding protection without sacrificing optical clarity, whether they are used on a high-end camera lens or a smartphone camera module.

To obtain the correct form and thickness, sapphire crystal lens covers are manufactured using precise cutting and polishing. These covers are then treated to enhance their scratch resistance further. The result is a robust lens cover that not only protects the underlying lens but also maintains optimal image quality over time. Sapphire crystal lens covers have become a hallmark of premium optical devices, symbolizing durability, clarity, and uncompromised performance.

What are the Specifications of Sapphire Optical Lenses?

Sapphire optical lenses come in a variety of specifications, catering to different applications and industry requirements. These specifications include the lens diameter, focal length, curvature, and surface quality. The diameter of the lens defines its size, which can range from tiny microlenses used in medical equipment to bigger lenses used in imaging systems. On the other hand, the focal length determines how far the lens is from the focal point, which has an impact on the lens’s capacity to focus and magnify.

In figuring out if a lens is convex or concave, curvature is a key factor in sculpting the lens surface. This curvature affects the convergence or divergence of light rays, which affects the overall optical behavior of the lens. Surface quality refers to the smoothness and precision of the lens surface, directly affecting image clarity and distortion. Sapphire optical lenses are manufactured with high precision, ensuring tight tolerances and superior surface quality.

Applications of Sapphire Optical Lenses

Sapphire optical lenses’ wide range of uses across numerous industries is evidence of their adaptability. Highly efficient cameras, targeting structures, and missile navigation systems all use sapphire lenses in the aerospace and defense industries. Their exceptional clarity and durability make them ideal for capturing sharp images and tracking moving objects accurately.

In the medical industry, sapphire lenses find applications in endoscopes, laser systems, and medical imaging devices. The scratch-resistant nature of sapphire ensures the lenses remain clear and functional, even after repeated sterilization processes. In the realm of scientific exploration, experts rely on sapphire lenses for instruments like spectroscopes and microscopes, emphasizing precision and reliability.

Furthermore, these sapphire optical lenses find essential roles in industrial laser setups, barcode scanners, and high-power laser diodes, showcasing their versatility and importance in various technological applications. Their ability to withstand intense laser beams without damage makes them indispensable in these applications. Sapphire lenses also play a vital role in high-end optical devices like digital cameras and professional lenses, where image quality and durability are of utmost importance.

Common Grades of Sapphire Lenses

Different grades of sapphire lenses can be obtained, each suited to particular uses and performance standards. Sapphire comes in a variety of typical grades, including optical, technical, and laser qualities. Optical-grade sapphire exhibits exceptional clarity and is suitable for applications where optical transparency is crucial. It is widely used in cameras, microscopes, and optical sensors, delivering sharp and distortion-free images.

Technical-grade sapphire offers a balance between optical clarity and mechanical strength, making it suitable for applications where both durability and decent optical performance are required. This grade finds applications in windows, protective covers, and sensor components in harsh environments. On the other hand, sapphire that has been laser-graded is designed specifically to endure strong laser beams without being harmed. As a result of its superior thermal insulation and toughness, it is perfect for laser optics, particularly the laser rods and lenses used in innovative laser equipment.

Different Surface Finishes of Sapphire Optical Lenses

The surface finish of sapphire optical lenses plays a crucial role in determining their optical performance. These lenses can be finished to various levels, ranging from standard commercial finishes to precision-polished surfaces. Standard commercial finishes are suitable for applications where moderate optical quality is acceptable, such as protective windows and basic optical components.

For applications demanding higher optical performance, sapphire lenses can undergo precision polishing processes. These processes involve careful polishing and fine grinding to achieve exceptional surface smoothness and flatness. Precision-polished sapphire lenses are used in advanced imaging systems, scientific instruments, and laser optics, ensuring superior image clarity and minimal light scattering.

Why Use Sapphire Optical Lens?

The choice to use sapphire optical lenses is rooted in their unmatched combination of hardness, transparency, and thermal conductivity. The outstanding scratch resistance of sapphire ensures long-lasting clarity, making it ideal for lenses in demanding environments. Whether exposed to abrasive particles or harsh chemicals, sapphire lenses remain unblemished, providing reliable optical performance over time.

Furthermore, the broad transparency range of sapphire, spanning from ultraviolet to near-infrared wavelengths, allows for versatile applications across diverse industries. This transparency ensures that sapphire lenses accurately transmit light without distortion, making them invaluable in precision optical instruments, cameras, and laser systems. The high thermal conductivity of sapphire ensures stable optical performance even in fluctuating temperature conditions, making it a preferred choice for critical applications where thermal stability is essential.

How to Choose the Right Sapphire Optical Lenses Manufacturer?

Choosing the right Sapphire Optical Lenses Manufacturer is a critical decision that can significantly impact the quality of your optical devices and applications.

When making your decision, keep the following important aspects in mind:

Expertise and Experience

Seek out manufacturers who have a strong history and substantial expertise in crafting sapphire optical lenses. Choosing a manufacturer with years of hands-on experience increases the likelihood of receiving top-notch products tailored to the unique needs of diverse industries, ensuring quality and reliability.

Quality Standards

Make sure the manufacturer you choose is committed to maintaining high-quality standards and obtaining certifications. It’s a good idea to opt for manufacturers that adhere to global standards such as ISO (International Organization for Standardization) to ensure that their products are of top-notch quality and dependable.

Customization Capabilities

Opt for a manufacturer that offers customization options. Every application may have unique requirements, so the ability to create tailor-made sapphire lenses according to your specifications is crucial. This customization ensures that the lenses perfectly fit your devices and meet your specific needs.

Advanced Technology and Equipment

Think about manufacturers who put their resources into cutting-edge manufacturing technology and the latest equipment. Up-to-date machinery guarantees precision and efficiency during production, resulting in top-quality lenses. Inquire about their manufacturing processes and the technology they use to create sapphire lenses.

Material Quality

Sapphire lenses are only as good as the quality of the sapphire material used. Ensure the manufacturer sources high-quality synthetic sapphire that is free from impurities and defects. The purity of the sapphire material directly affects the optical clarity and performance of the lenses.

R&D Capabilities | Sapphire optical lens

A manufacturer with strong research and development capabilities is more likely to innovate and offer cutting-edge solutions. Manufacturers engaged in ongoing research are aware of the latest trends and advancements in sapphire optics, ensuring that you receive lenses with the latest technological enhancements.

Reputation and Reviews

Research the manufacturer’s reputation in the industry. Read customer reviews and testimonials to gauge the satisfaction levels of their clients. Positive feedback from other customers indicates the manufacturer’s reliability and customer service quality.

Support and Customer Service

Consider the level of customer support provided by the manufacturer. Opt for a manufacturer that offers excellent customer service, prompt communication, and technical support. A responsive manufacturer can address your concerns and queries effectively, ensuring a smooth collaboration process.

Cost and Lead Time

Even if price is an important consideration, it shouldn’t be the only one. Achieve a balance between price, product quality, and the reputation of the maker. Additionally, consider the lead time for production and delivery. Choose a manufacturer that can deliver within your required timeframe without compromising quality.

Environmental Responsibility

In today’s environmentally conscious world, consider manufacturers who adhere to eco-friendly practices. Manufacturers that prioritize sustainability demonstrate social responsibility and a commitment to minimizing their environmental impact.

By carefully evaluating these factors and conducting thorough research, you can select a Sapphire Optical Lenses Manufacturer that not only meets your current needs but also establishes a long-term partnership based on quality, reliability, and innovation.

In conclusion, sapphire optical lenses stand as a testament to human ingenuity, harnessing the unique properties of this remarkable material to advance technology and enhance our understanding of the world. Their durability, clarity, and thermal stability make them indispensable in industries where optical precision is non-negotiable. By choosing sapphire lenses, professionals and enthusiasts alike invest in the future of optics, ensuring that clarity and precision remain at the forefront of technological innovation.

sapphire optical lens